Structural Inspection

Assess buildings, identifying defects through detailed analysis to ensure safety and longevity effectively.

Research topics

What is a Structural Inspection?

Structural inspection is an essential process that ensures the safety, integrity, and longevity of various structures, from bridges to buildings. This comprehensive examination aims to identify any potential problems that could lead to structural failure or safety hazards. Through this process, inspectors utilize various techniques, ensuring that materials used in construction meet necessary standards. Different types of inspections fall under this umbrella, including Visual Inspection, Concrete Inspection, and specialized non-destructive testing (NDT) methods.

The Importance of Material Testing

One of the cornerstones of a successful structural inspection is Material Testing. This refers to the systematic examination of the material’s properties and behaviors under various conditions. Testing helps in determining the strength, flexibility, durability, and resistance of materials to weathering, corrosion, and wear over time. Without thorough material testing, it's impossible to ensure that a structure will perform as expected. Engineers often rely on detailed reports from inspections to make informed decisions regarding design, repair, or maintenance.

Non-Destructive Testing (NDT) Methods

NDT is a suite of techniques used to evaluate the properties of a material, component, or system without causing damage. Common NDT methods include Ultrasonic Testing, Radiographic Testing, and Eddy Current Testing. Each of these testing methods has unique advantages that make them suitable for specific applications within structural inspections. For example, ultrasonic testing uses high-frequency sound waves to detect internal flaws in materials, while radiographic testing employs X-rays to visualize the internal structure of an object.

Types of NDT Methods

Ultrasonic Testing is one of the most widely used forms of NDT. It is particularly effective in identifying internal defects in materials. By sending sound waves through materials, technicians can identify changes in material properties or detect voids, cracks, and inclusions that could compromise structural integrity. These findings can be critical in maintaining safety standards and avoiding catastrophic failures.

Radiographic Testing is another powerful tool in the structural inspection toolkit. By utilizing X-rays or gamma rays, this method provides a view of the internal structure of a component. It is invaluable for identifying defects that may not be visible on the surface, making it ideal for critical applications such as welding inspections or checking for corrosion in pipelines.

Eddy Current Testing works on the principle of electromagnetic induction. It is particularly useful for detecting surface and near-surface defects in conductive materials. This method can determine the thickness of coatings, detect corrosion, and identify material properties accurately. Its speed and effectiveness make it a go-to choice in many inspection scenarios.

Complementary Inspection Techniques

While NDT methods are essential, they don’t operate in isolation for comprehensive structural inspections. Other techniques like Visual Inspection are crucial as well. Visual inspections rely on the keen eyes of trained inspectors to spot signs of distress, such as cracking, rust, and material degradation. Technicians often supplement visual inspections with NDT methods for a more detailed analysis of the structure's health.

Specialty Inspections

In addition to general structural inspections, specialized inspections like Concrete Inspection, Corrosion Inspection, Bridge Inspection, and Pipeline Inspection help address specific needs. For instance, concrete inspections evaluate the curing, strength, and overall condition of concrete structures. Corrosion inspection aims to analyze and mitigate the effects of corrosion, particularly in metals exposed to harsh environments.

Understanding Failure Analysis

Failure analysis plays a vital role in structural inspections and is often conducted when a failure has occurred or is suspected. This process involves investigating the cause of the failure, be it material fatigue, external loads, or design flaws. Understanding why a structure failed can help prevent future incidents and improve safety standards across the board. Inspection reports from past analysis can offer valuable insights for new projects.

The Process of Structural Inspection

A typical structural inspection begins with a visual walk-through by qualified inspectors, taking note of obvious issues like cracks, rust, or any visible signs of deterioration. Depending on initial findings, inspectors might recommend further NDT methods for a more detailed examination. This could involve decisions on sampling materials for more intensive Material Testing or possibly even conducting a Bridge Inspection or a Pipeline Inspection.

Compliance and Regulations

A significant aspect of structural inspections centers around compliance with local, state, and federal regulations. Adhering to proper guidelines is critical for the safety of all structural elements. In some cases, the results of structural inspections are reported to government agencies as part of compliance checks. For detailed information on government requirements for structural evaluation, please visit this link.

The Future of Structural Inspection

As technology continues to evolve, so does the field of structural inspection. Advancements like drone technology and robotic systems are starting to play a role in inspecting hard-to-reach areas, providing safer and more efficient inspection methods. The integration of AI in data analysis is also paving the way for predictive maintenance strategies, ensuring that structural integrity is maintained before issues arise.

Key Takeaways

In conclusion, structural inspection is an essential element in civil engineering and construction management. Whether it's using NDT methods like Ultrasonic Testing or conducting a Bridge Inspection, every aspect plays a role in ensuring safety. The significance of Material Testing cannot be understated, as it provides key insights into material behaviors that affect the overall integrity of structures. Incorporating comprehensive inspection strategies leads to safer infrastructure and fewer risks. If you're interested in learning advanced NDT practices, check out this resource: here and to find professional inspection services, consider this link for further assistance.

Thank you for following along in our exploration of structural inspection. If you have any inquiries or require further information, feel free to reach out!

Posts Relacionados

20 Percent Tablecloths Guide

This guide offers advice on choosing and caring for tablecloths.

3D Remodeling Tools

These tools allow users to create, modify, and optimize 3D models for various applications with precision.

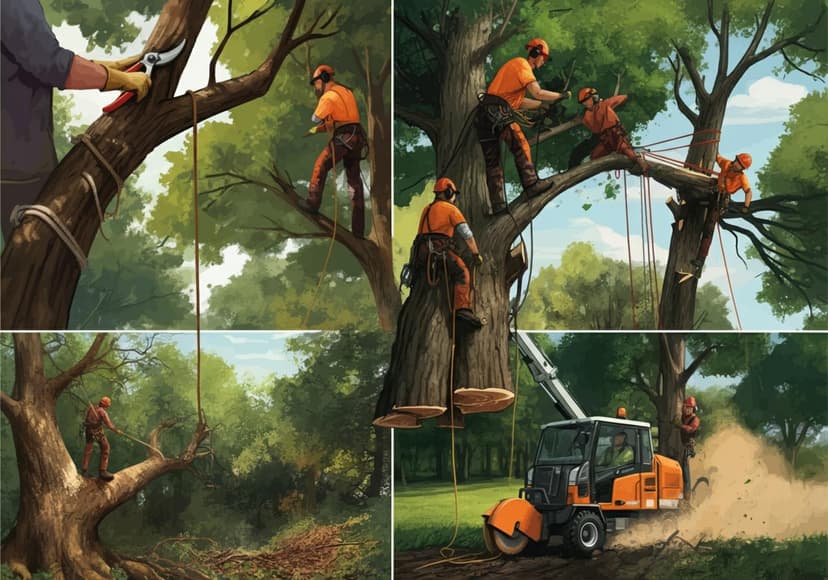

A1 Tree Trimming And Removal Guide

Proper tree trimming and removal ensures safety and enhances landscape aesthetics.